When you work out, you get warm. When it is hot out to begin with, and you are going as hard as you can, you get very warm. The same thing happens to the machines built for the heavy lifting. Heat breaks down lubricants, ages gaskets and shortens the lifespan of components. Robots are expected to pay back their investors with constant uptime.

A single failure of one of these machines can bring an entire assembly line to a halt. At the printed circuit board level, we designers need to provide the most robust solutions to keep the wheels turning under the autonomous taxi or on the factory floor.

“Cooling takes many strategies, and one of the main ones is derating the components.”

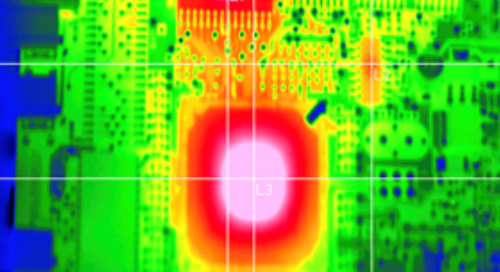

The most effective thing we can do is to spread out the components. Each one has a thermal signature that creates the warmer colors on the infrared image where heat becomes visible. Thicker boards with heavier copper will go a long way towards heat sinking. What if we don't have room to spread out or we have circuits that are too dense for thick conductors? As the current density increases, the temperature rise follows. To manage this puzzle, we have to understand the paths that the thermal energy will take.